CPM 3-7 HP

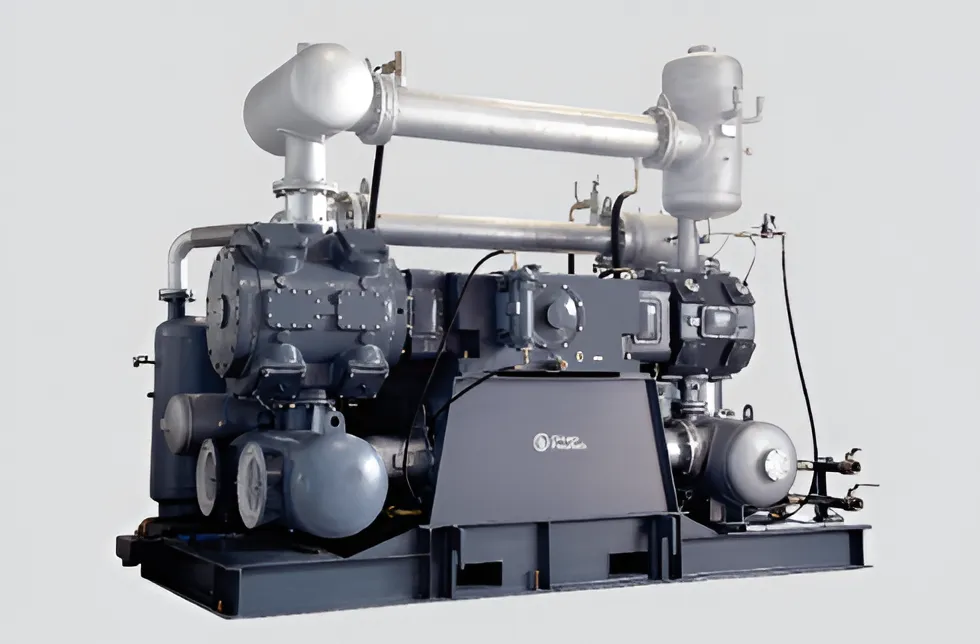

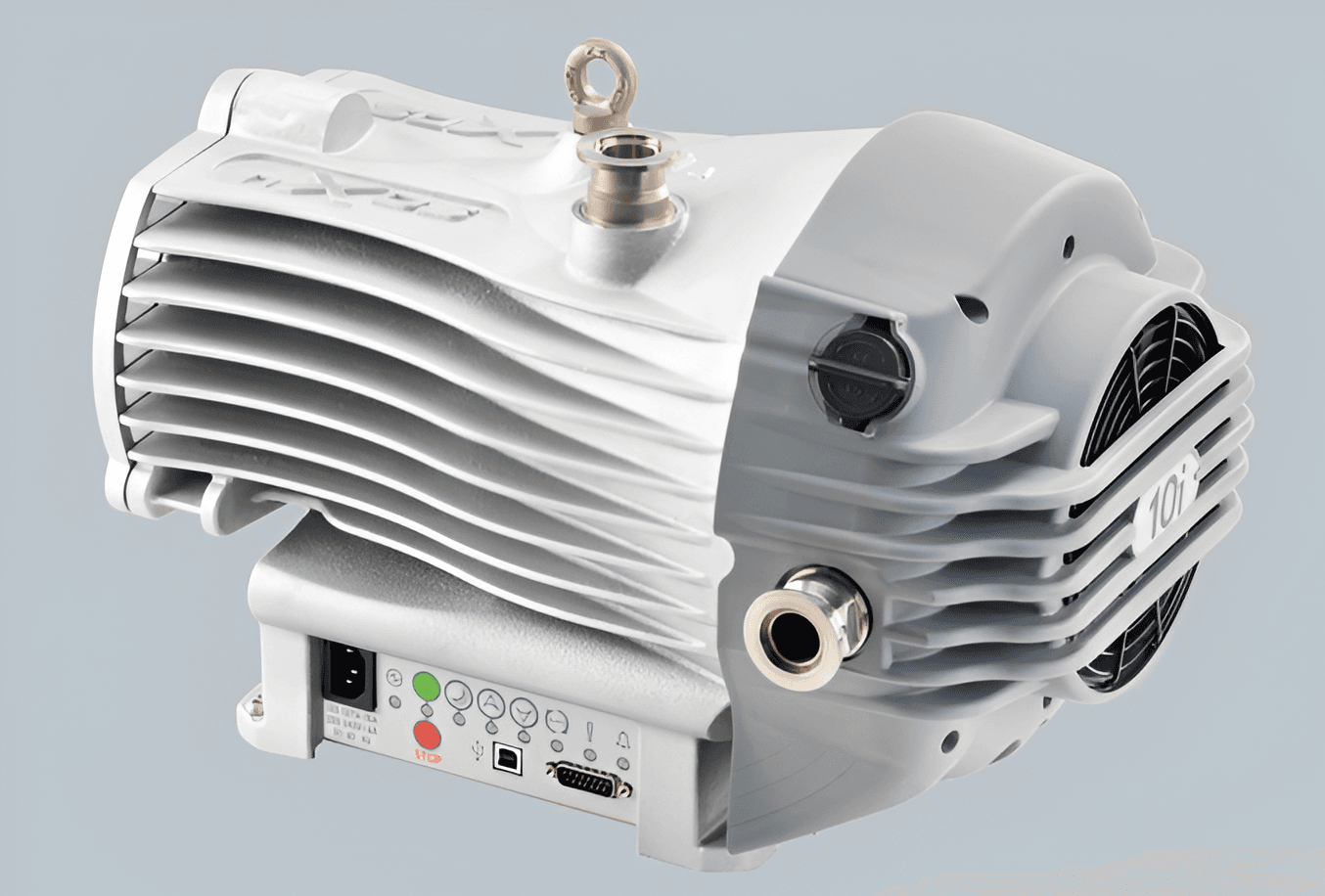

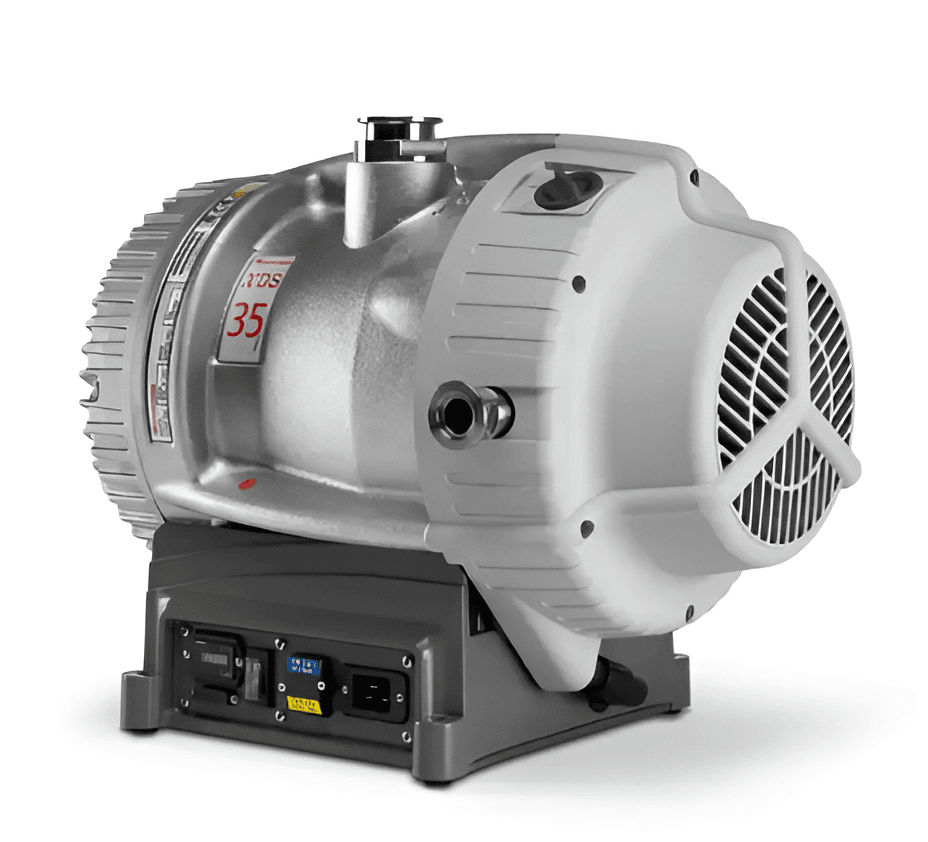

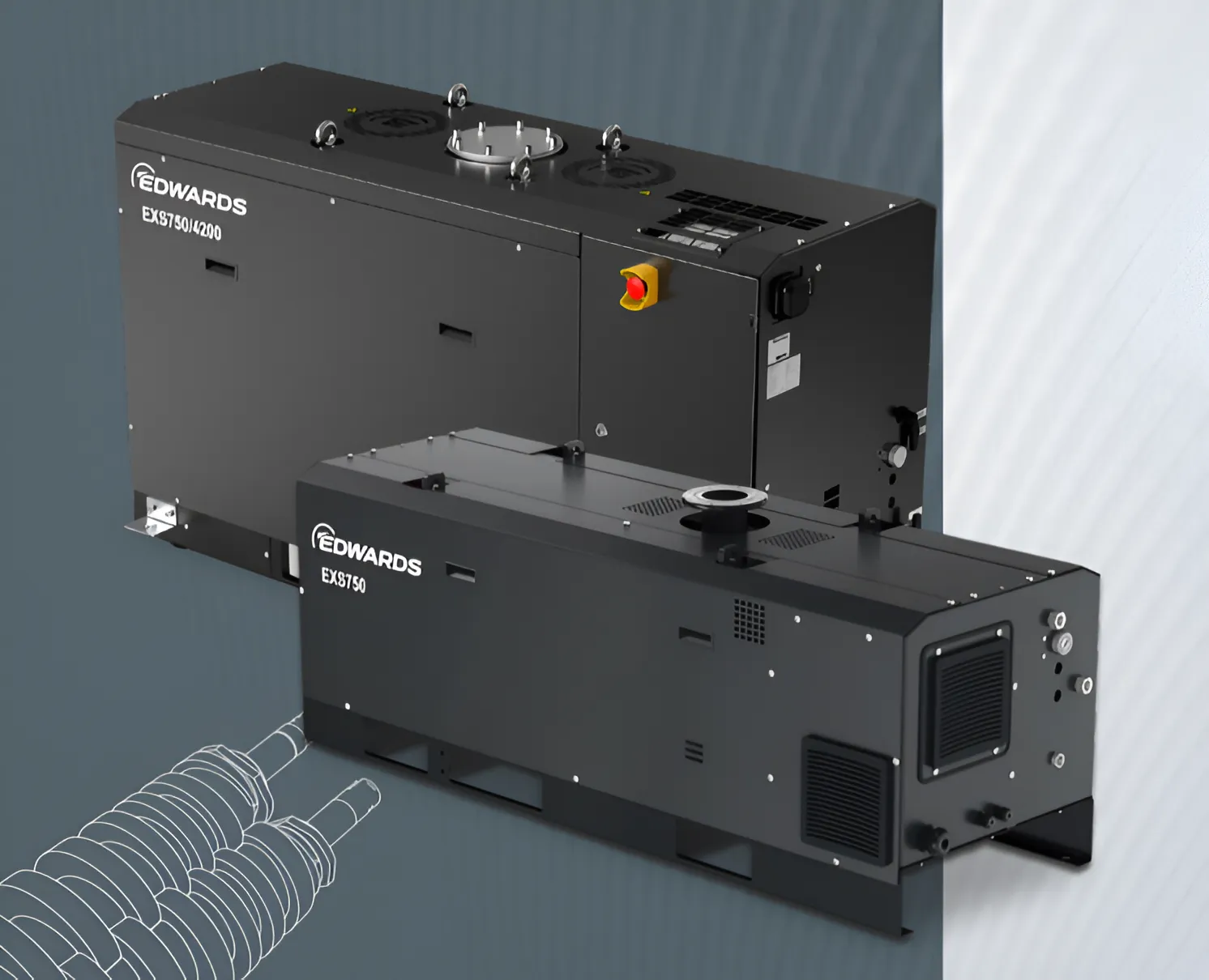

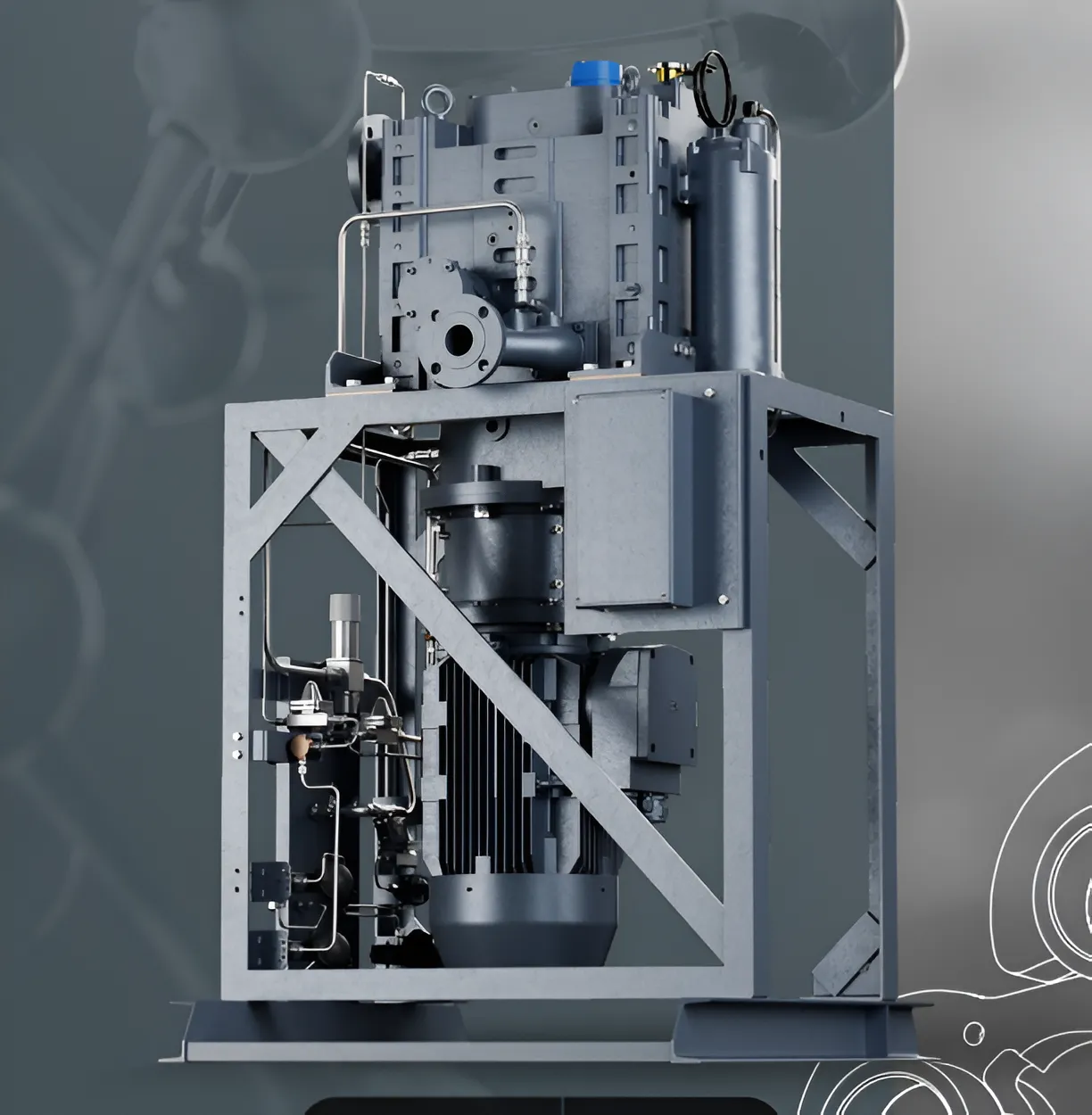

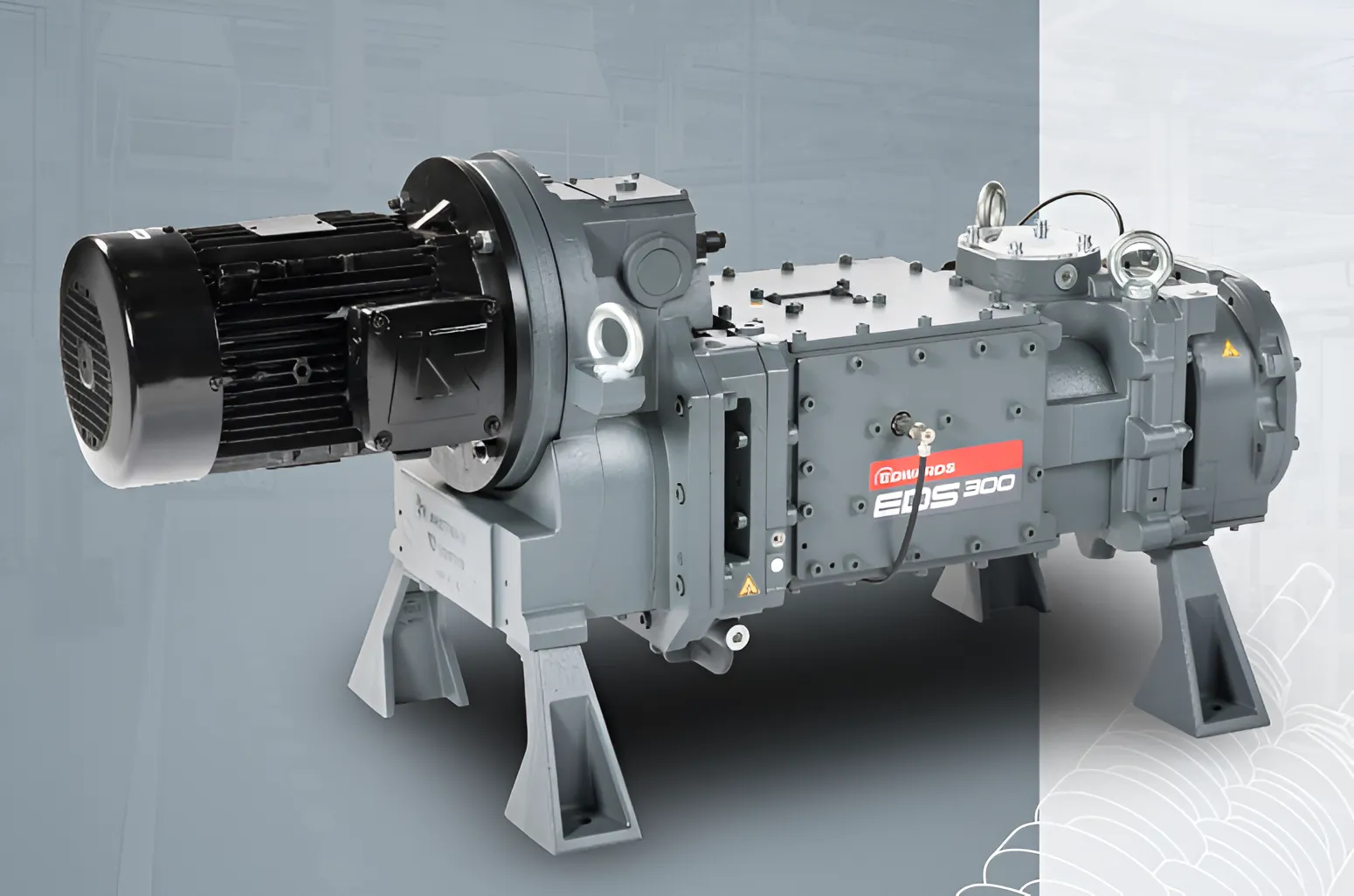

Engineered for high performance, efficiency, and reliability, the CPM air compressor series can meet the compressed air demands of a tire shop, maintenance shop, vehicle body shop, paint shop or automotive dealership. Quiet by design, the CPM can be installed almost anywhere, without disturbing your working environment. Base-mounted or receiver mounted, with or without a dryer, the CPM is the leading rotary screw compressor for service or light industrial applications.

| Model | HP | Pressure (BAR G) | CFM | dB(A) | End Connection | Weight (KG) TM | Weight (KG) TMD |

|---|---|---|---|---|---|---|---|

| CPM 3 | 3 | 10 | 8 | 61 | ½" | 175 | 209 |

| CPM 4 | 4 | 11 | 61 | 178 | 209 | ||

| CPM 5 | 5 | 16 | 62 | 182 | 216 | ||

| CPM 7 | 7.5 | 21 | 62 | 182 | 216 |

- Unit performance measured as per ISO 1217: 2009Ed4.

- Noise level measured according to ISO2151 / Pneurop / CAGI PN8NTC2.

- All models available with 200 L receiver tank.

- All models available with optional Refrigerated dryers (suffix D).

- Maximum working pressure for machines with dryer is 9.75 bar.

Key User Benefits

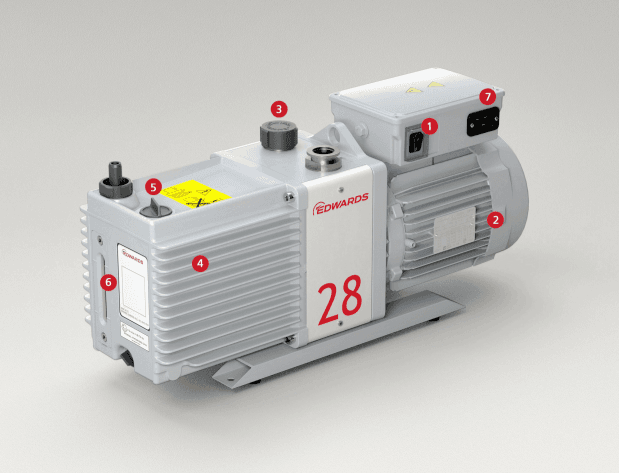

Easy Operation

Compressed air plain and simple. Just connect the cables, pipes and press start.

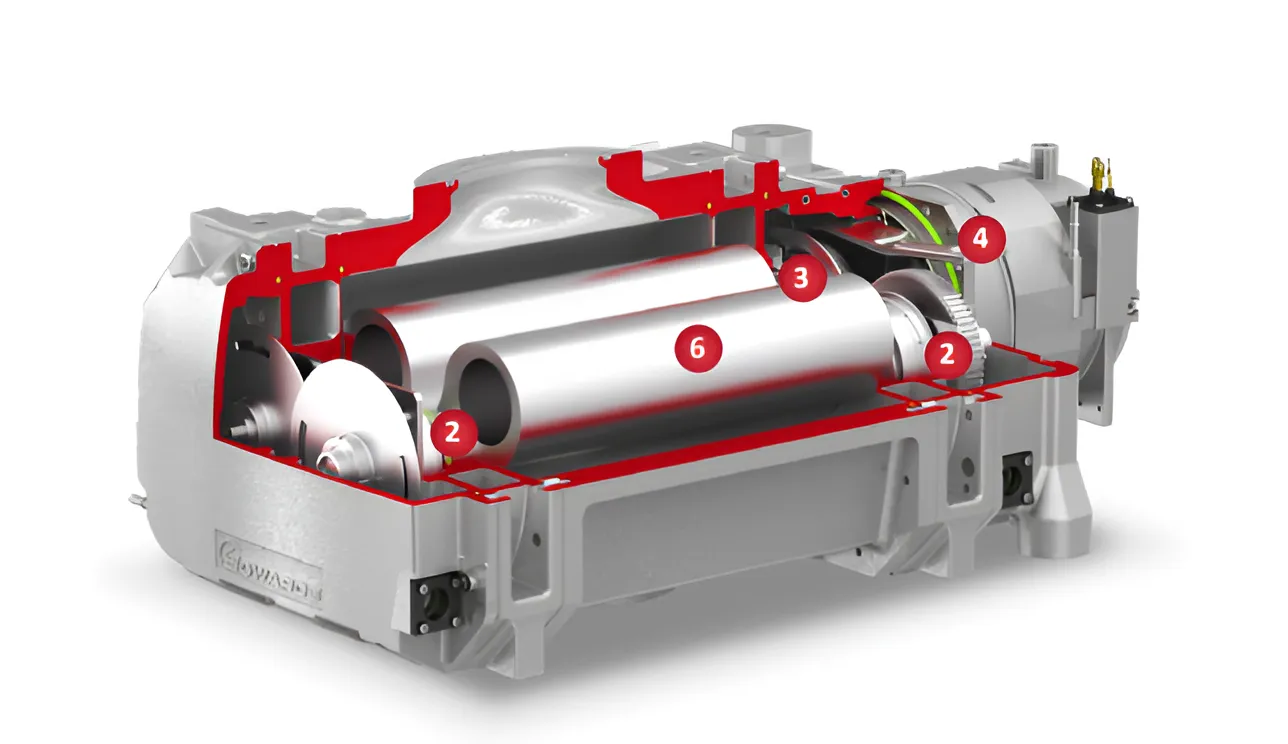

Efficient Cooling

Lower Tnternal Temperatures make your compressor more reliable and Extend Lifetime.

Built to Last

Designed for continuous duty and very hard working conditions.

Fast & Cost Effective Maintenance

No wearing parts: increases reliability and reduces maintenance costs.