HX Series

HX Series

Technical Data

| Model (Vertical-Normal Pressure) | Capacity FAD* | Max Working Pressure | Capacity FAD* | Max Working Pressure | Installed Motor Power (HP) | ||||

|---|---|---|---|---|---|---|---|---|---|

| m³/min | cfm | bar (e) | psig | m³/min | cfm | bar (e) | psig | ||

| HX1T-15NP/PS | 1.19 | 42 | 10 | 145 | 1.70 | 60 | 7 | 102 | 15 |

| HX1T-20NP/PS | 1.98 | 70 | 9 | 131 | 2.44 | 86 | 7 | 102 | 20 |

| HX1T-25N1P/PS | 2.46 | 87 | 9 | 131 | 2.83 | 100 | 7 | 102 | 25 |

| HX1T-25N2P/PS | 2.69 | 95 | 9 | 131 | 3.23 | 114 | 7 | 102 | 25 |

| HX1T-30NP/PS | 3.17 | 112 | 9 | 131 | 3.85 | 136 | 7 | 102 | 30 |

| Model (Horizontal, Two Cylinder, Balanced-Opposed Models) | Capacity FAD* | Max Working Pressure | Capacity FAD* | Max Working Pressure | Installed Motor Power (HP) | ||||

|---|---|---|---|---|---|---|---|---|---|

| m³/min | cfm | bar (e) | psig | m³/min | cfm | bar (e) | psig | ||

| HX2T-30NP | 3.45 | 122 | 10 | 145 | 4.47 | 158 | 7 | 102 | 30 |

| HX2T-40NP | 5.35 | 189 | 10 | 145 | 6.31 | 223 | 7 | 102 | 40 |

| HX2T-50NP | 6.06 | 214 | 10 | 145 | 7.73 | 273 | 7 | 102 | 50 |

| HX2T-60NP | 8.01 | 283 | 10 | 145 | 9.30 | 327 | 7 | 102 | 60 |

| HX2T-75NP | 9.17 | 324 | 10 | 145 | 11.67 | 412 | 7 | 102 | 75 |

| HX2T-100NP | 13.37 | 472 | 10 | 145 | 14.84 | 524 | 7 | 102 | 100 |

| HN2T-120NP/PS | 16.31 | 576 | 10 | 145 | 18.06 | 638 | 7 | 102 | 120 |

| HN2T-150NP/PS | 19.31 | 682 | 10 | 145 | 23.13 | 817 | 7 | 102 | 150 |

| HN2T-180NP/PS | 23.19 | 819 | 10 | 145 | 26.11 | 922 | 7 | 102 | 180 |

| HN2T-215NP | 27.04 | 955 | 10 | 145 | 33.47 | 1182 | 7 | 102 | 215 |

| Model (Vertical-Low Pressure) | Capacity FAD* | Max Working Pressure | Capacity FAD* | Max Working Pressure | Installed Motor Power (HP) | ||||

|---|---|---|---|---|---|---|---|---|---|

| m³/min | cfm | bar (e) | psig | m³/min | cfm | bar (e) | psig | ||

| HX1T-25L P/PS | 4.59 | 162 | 4 | 58 | 5.21 | 184 | 2.5 | 36 | 25 |

| HX1T-30L P/PS | 5.10 | 180 | 4 | 58 | 6.63 | 234 | 2.5 | 36 | 30 |

| Model (Horizontal, Two Cylinder, Balanced-Opposed Low Pressure) | Capacity FAD* | Max Working Pressure | Capacity FAD* | Max Working Pressure | Installed Motor Power (HP) | ||||

|---|---|---|---|---|---|---|---|---|---|

| m³/min | cfm | bar (e) | psig | m³/min | cfm | bar (e) | psig | ||

| HX2T-50LP | 9.40 | 332 | 4 | 58 | 11.92 | 421 | 2.5 | 36 | 50 |

| HX2T-75LP | 13.99 | 494 | 4 | 58 | 17.73 | 626 | 2.5 | 36 | 75 |

| HX2T-100LP | 18.69 | 660 | 4 | 58 | 22.12 | 781 | 2.5 | 36 | 100 |

| HN2T-120L P/PS | 21.80 | 770 | 4 | 58 | 30.16 | 1065 | 2.5 | 36 | 120 |

| HN2T-150L P | 28.94 | 1022 | 4 | 58 | 37.07 | 1309 | 2.5 | 36 | 150 |

| HN2T-180L P/PS | 36.02 | 1272 | 4 | 58 | 46.55 | 1644 | 2.5 | 36 | 180 |

| HN2T-215L PS | 40.46 | 1429 | 4 | 58 | 45.59 | 1610 | 3 | 44 | 215 |

| Model (VSD Drive Models) | Capacity Min* | Capacity FAD Max* | Min Working Pressure | Max Working Pressure | Installed Motor Power (HP) | ||||

|---|---|---|---|---|---|---|---|---|---|

| m³/min | cfm | bar (e) | psig | m³/min | cfm | bar (e) | psig | ||

| VX 50 NP-VSD | 2.15 | 76 | 5.38 | 190 | 5 | 73 | 10 | 145 | 50 |

| VX 75 NP-VSD | 3.31 | 117 | 8.30 | 293 | 5 | 73 | 10 | 145 | 75 |

| VX 120 NP-VSD | 5.04 | 178 | 12.63 | 446 | 5 | 73 | 10 | 145 | 100 |

| VN 150 NP/PS-VSD | 6.54 | 231 | 16.37 | 578 | 5 | 73 | 10 | 145 | 120 |

| VN 215 NP/PS-VSD | 8.49 | 300 | 21.32 | 753 | 5 | 73 | 10 | 145 | 150 |

| VN 240 NP/PS-VSD | 11.13 | 393 | 26.56 | 938 | 5 | 73 | 10 | 145 | 180 |

Features & Benifits

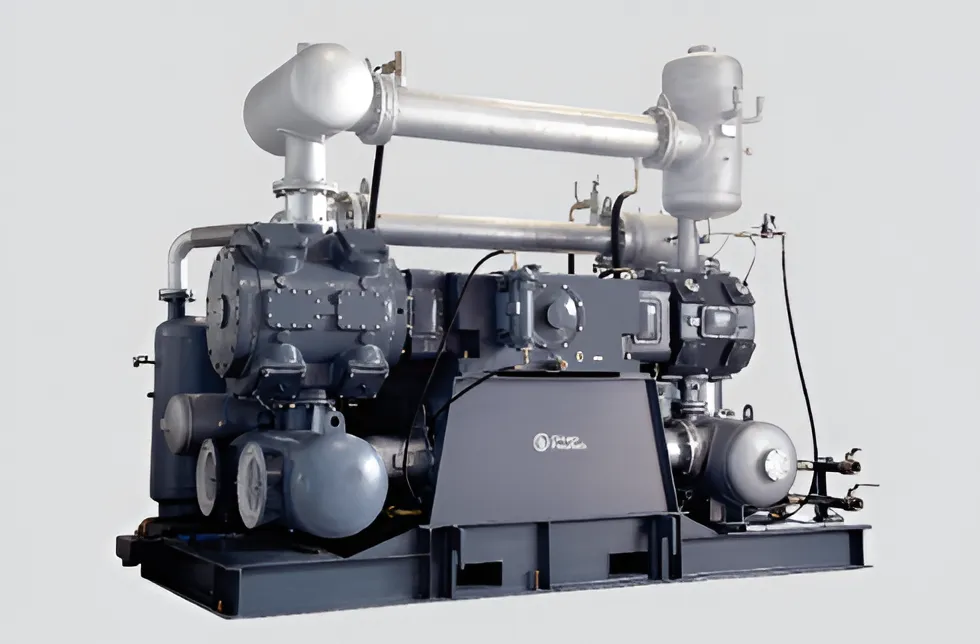

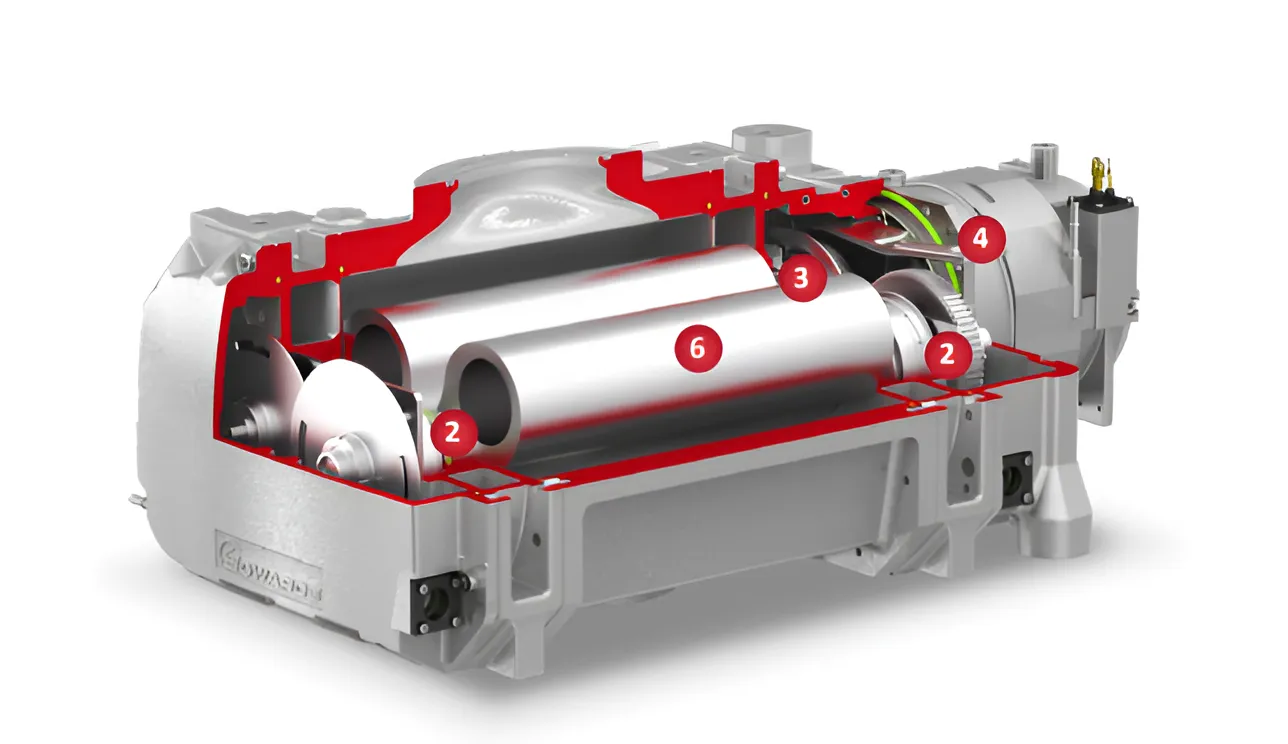

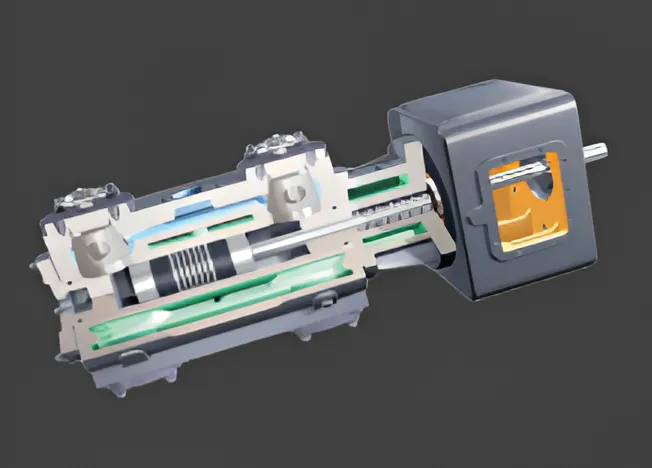

Horizontal Balanced Opposed Design

Chicago Pneumatic oil-free compression chamber ensures your demand of 100% oil-free compressed air is met to the fullest.

Our oil-free cylinders with PTFE rings and extra-long distance guarantees oil-free air for your critical process.

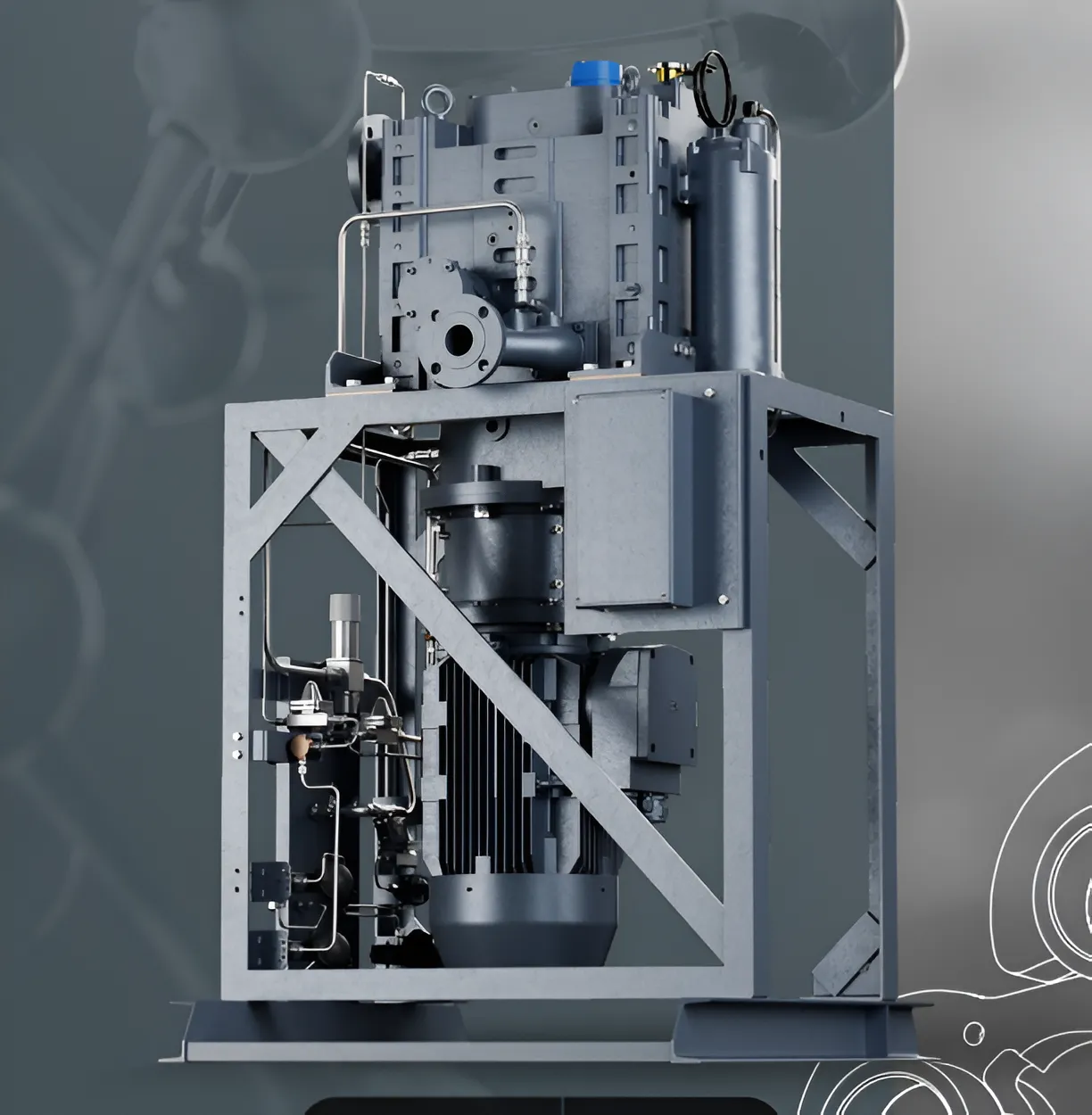

The machine is packaged & tested as per BS 1571 Part-II.

Totally integrated package with our time-tested oil-free piston technology comes as plug & play unit.

Monitor critical parameter during operation.

Overall system performance with pro-active service indications & safety features.

All monitoring & control functions through a single interface.

Integration with external communication system like Modbus, Profibus, etc.

Designed for 24x7 Industrial Applications, meets your continuous need for compressed air.

Time Proven 2/3/4 stage Compression process.

Superior Stainless steel valves, precise sizing, and selection of every component for high efficiency and reliable performance.

Horizontal BOP design and dynamically balanced arrangement leads to lesser vibration levels.

The machine comes with a unique base frame design & special elastomer AVM, needing no special foundation.

Superior Stainless steel valves, precise sizing, and selection of every component for high efficiency and reliable performance.

The professionally designed Star-Delta starter panel integrated on the compressor skid.

Option of Integrated VSD Panel ensures what you pay for what you use.

The design provides easy access to components for trouble-free operations.

Thanks to our wide range of options, we can customize compressors to meet your precise needs. Our extensive experience recognized in engineered machines as per API 618 compliance, provides end-to-end solutions to customers.

Diversified in Air & N2 applications.

Integrated Timer-based Auto drain eliminates the risk of moisture content in compressed air.

Effective moisture separation. Committed to providing Quality Air to your process & applications.

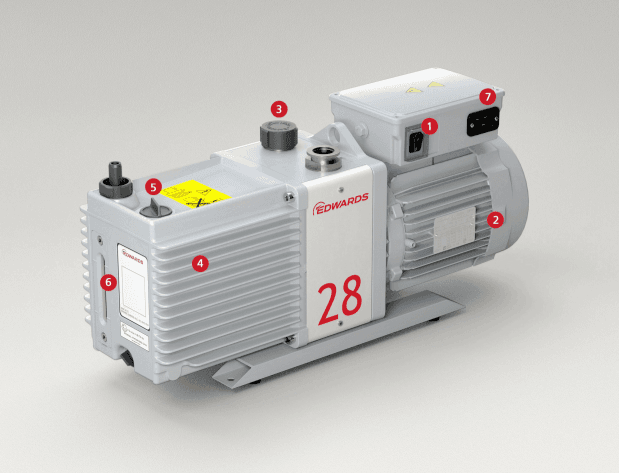

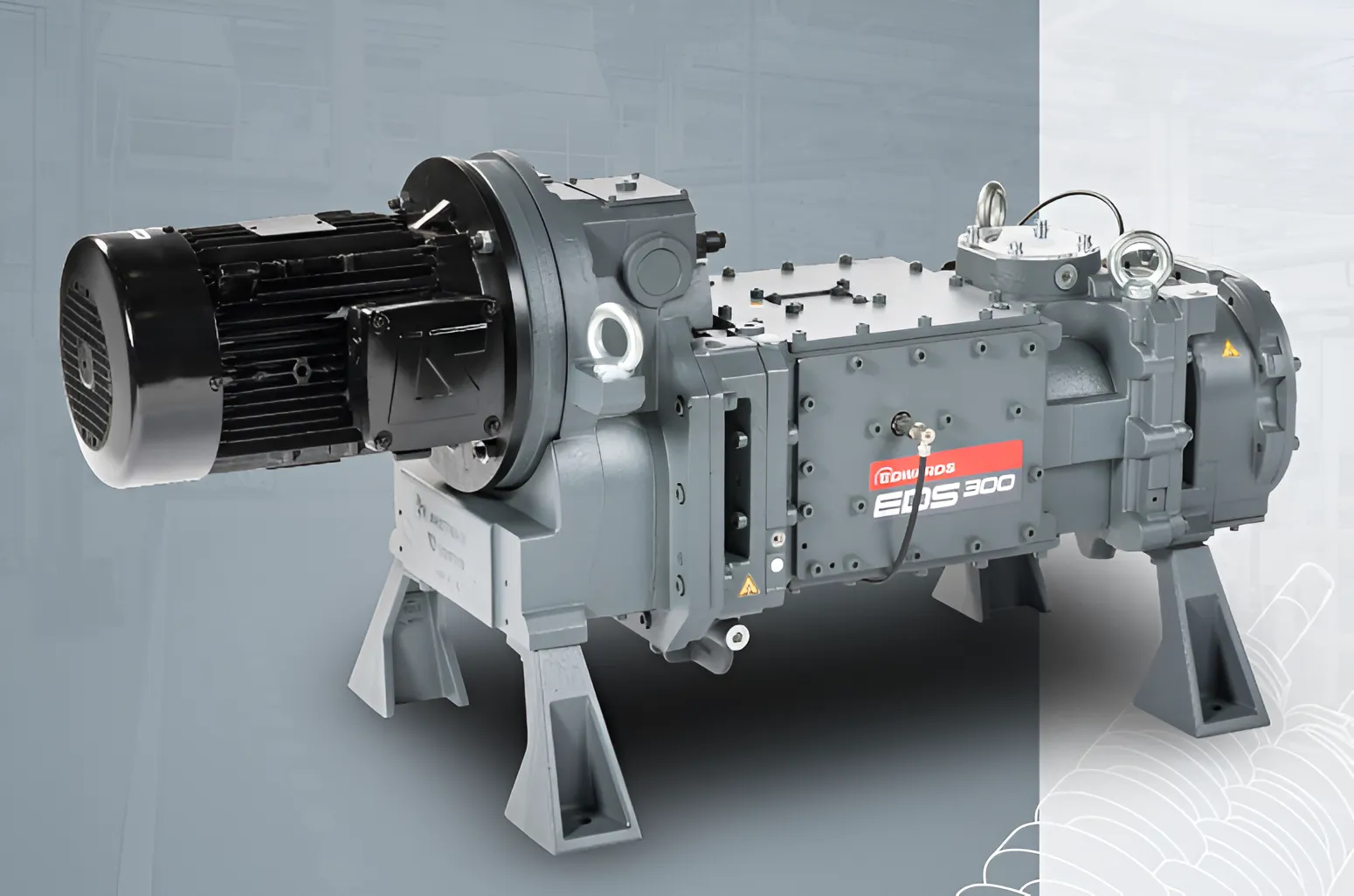

The energy-efficient TEFC design motor is designed for 50 Deg C Ambient condition with IP 55 protection.

These motors are rated for continuous duty and low-speed design for longer life. Intelligent 3-part belt guard design ensures easy assembly and dismantle process.

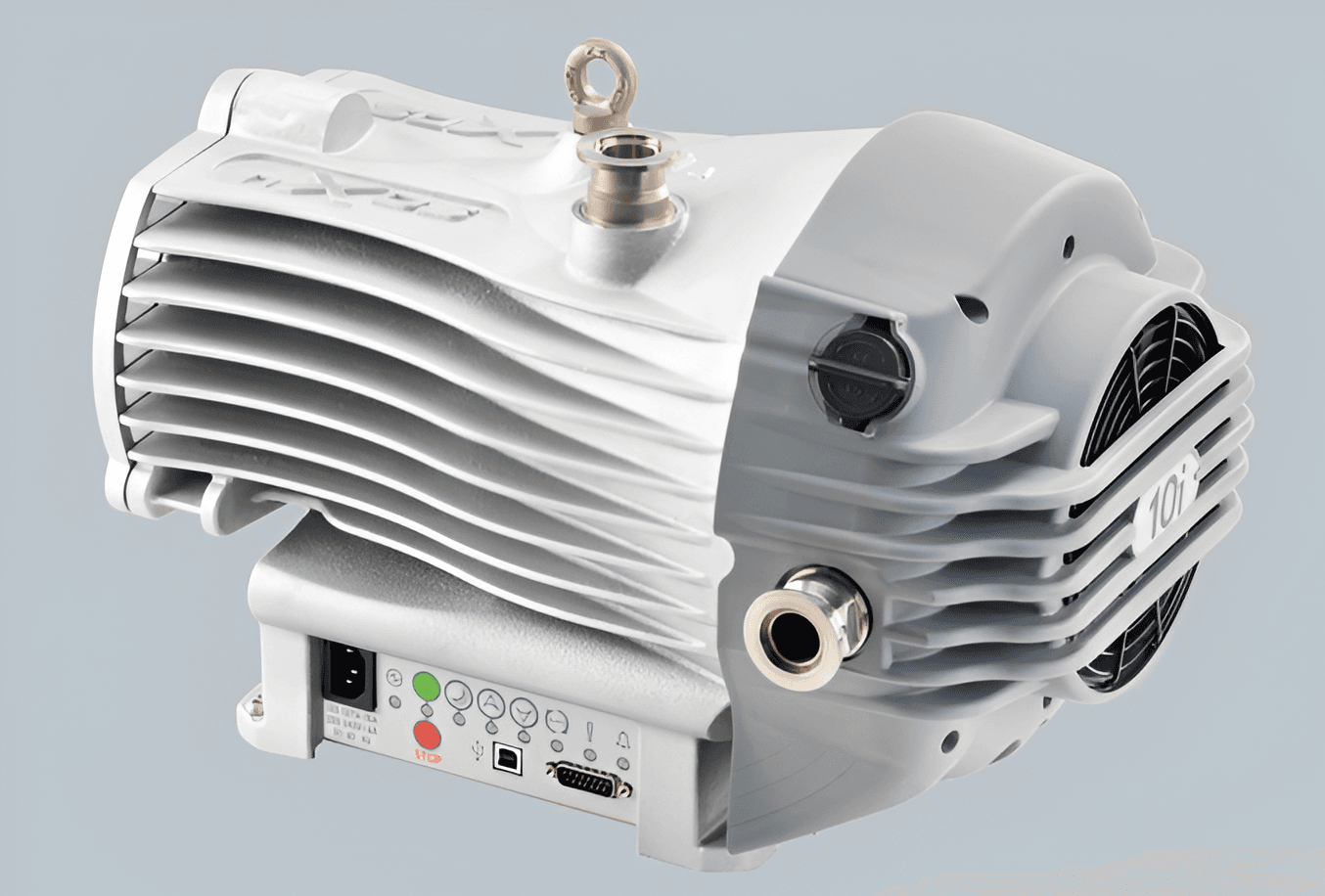

Smarter control

HX/HN series machines are extremely energy efficient. The smarter controller adapts to your air requirements and ensures that the process is extremely flexible & efficient. Different capacity controls are possible with this advanced unit.

Stepped Control - Double acting cylinders allow the flow to be adjusted by clamping one or several suction valves in the open position. Stepped capacity control of 0-100% is possible with more advanced control as per process requirement.

Bypass - The use of a Pressure control valve gives an extremely stable pressure. Narrow pressure band gives flexibility to deliver the performance at optimum regime.

Variable Speed Drive - PXi Series machines with double acting cylinders, Variable Speed Drive - VX/VN capacity control allows step-less capacity control, optimizes energy consumption and ensures process stability.

ICONS

Always be connected at all times with Icons that help to optimize your compressed air consumption and saves on cost/energy.

It offers complete insight into your compressed air network through a secured network.

Protecting your equipment by anticipating potential problems by warning you upfront.

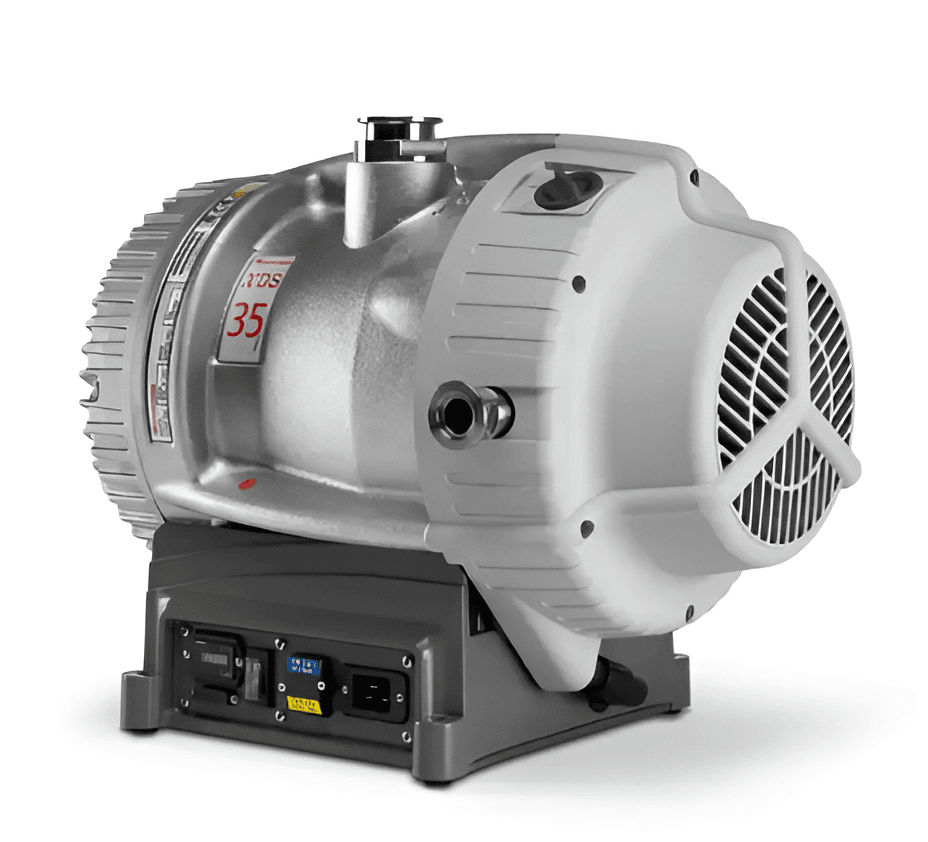

Inverter

Variation in air demand is almost 90% of all installations. In almost every production process, air demand fluctuates depending on different factors (time of the day, week, or even month).

Detailed analysis and studies of compressed air demand cycle show that 80% of all compressor installations have substantial variations in air demand. Only 20% of all installations have a more stable air demand. In this scenario, inbuilt Inverter drive compressors save substantial energy. Energy consumption typically represents over 80% of a compressor's Life Cycle Cost.

To reduce costs and provide innovative solutions, We at Chicago Pneumatic Compressors have pioneered the Inverter drive technology. Inverter drive provides major energy savings while protecting the environment for future generations. Our continual investments in R&D enable us to offer the widest range of integrated Inverter drive compressors for the market.